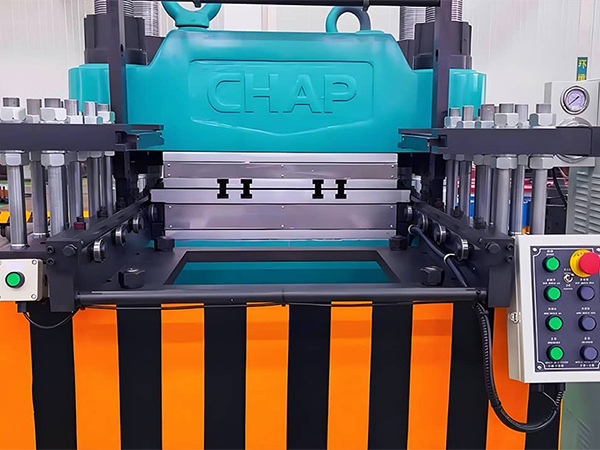

Plate Vulcanizing Press for Rubber

The plate rubber vulcanizing machine is the main molding equipment for various rubber molded vulcanized products and non-molded rubber products. Its characteristics include a simple structure, high pressure, wide applicability and high efficiency.

This series of plate vulcanizing machines are suitable for the compression molding of thermoset plastics, foams, resins, bakelite, thin metal, building materials and other molded products.

This series of equipment has a single-layer machine with transfer molding, double-layer machine without transfer molding and so on. Users can choose the best one for their needs based on application requirements.